Pompe Garbarino SpA, an Italian company founded in 1932, is a leading manufacturer of centrifugal and positive displacement navy pumps, and pumps for the shipbuilding industry.

The company has two factories in Acqui Terme (AL) and a worldwide network of agents and service centres.

Garbarino focuses on the constant improvement of its products supported by excellent service to customers in terms of technical consultancy and after sales service ensuring the availability of engineers on site. Spares delivery and product replacement can be guaranteed in very short time thanks to the huge capacity of the warehouse, one of the best strength’s points of the company.

Naval pump applications

Garbarino’s centrifugal and positive displacement pumps’ naval applications include seawater main cooling systems, ballast and bilge services, firefighting and general services, water circulation, A/C chilled water circulation, boiler feed, lube oil or fuel oil transfer applications, waste oil transfer, scrubber, and ballast water treatment systems.

They can be located on aircraft carriers, submarines, frigates, corvettes, mine-hunters, destroyers, patrol boats and oceanographic vessels.

Centrifugal pumps

Garbarino’s range of centrifugal pumps includes:

- Pumps according to EN 733 standards (MU)

- Vertical in-line (MU-L) and vertical in-line double suction (MU-LDS) pumps

- Vertically suspended line-shaft pumps (VS)

- Recessed impeller torque flow pumps (MCA)

- Multistage high-pressure pumps (G/GH)

- Side channel pumps (BT)

- Portable diesel engine fire pumps (MU-MPF)

- Fire-fighting split casing naval pumps (MMI)

- Main engine lubrication pumps (VL)

- Self-priming pumps with open impeller (AD)

Positive displacement pumps

Gear (IN), hollow oscillating disk (P) and piston (SWL) pumps are also produced by Garbarino.

Customised shipbuilding pumps

Garbarino’s flexibility allows it to develop naval and shipbuilding pumps according to its clients’ needs and high-quality standards.

A selection of material such as cast iron, nickel-aluminium bronze (Ni-Al-Bz), stainless steel, duplex, super duplex, Hastelloy, monel or any other alloy or superalloy is available to be used depending on the customer’s specifications and the particular duties the product is required to perform.

A qualified pump-supplier

Since 1983, Garbarino operations have applied and maintained the quality assurance standards set by Nato AQAP and UNI EN 29000 directives.

The operations adopted by Garbarino and the suitability have been certified by the Italian Naval Ministry of Defence.

Presently, Garbarino is granted by Nato AQAP 2110, ISO 9001:2015 and ISO 14001:2015.

Pumps meet the requirements of the following standards:

- MIL-STD 167-1 (mechanical vibrations)

- MIL-STD 740-1 (airborne sound)

- MIL-STD 740-2 (structure-borne vibrations)

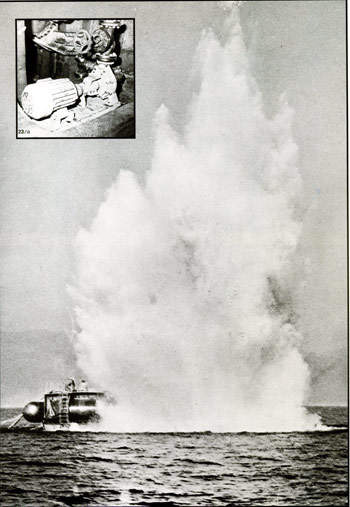

- MIL S 901-D (shock test)

- Non-magnetic pump executions

A successful naval-pump supplier

Garbarino, the official supplier of the Italian Navy since 1950, also supplies for the following foreign navies:

- French Navy

- Spanish Navy

- Finnish Navy

- Royal Norwegian Navy

- Royal Netherlands Navy

- Belgium Navy

- Hellenic Navy

- Polish Navy

- Bulgarian Navy

- Russian Navy

- Iraqi Navy

- Qatari Navy

- United Arab Emirates (UAE) Navy

- Royal Navy of Oman

- Bangladesh Navy

- Republic of China Navy

- Philippine Navy

- Royal Thai Navy

- Royal Malaysian Navy

- Singapore Navy

- Indonesian Navy

- Algerian Navy

- Royal Moroccan Navy

- Libyan Navy

- Nigerian Navy

- Angolan Navy

- South African Navy

- Mexican Navy

- Venezuelan Navy

- Ecuadorian Navy

- Peruvian Navy

- Brazilian Navy

It also supplies for the following naval shipyards:

- Fincantieri – Italy

- Intermarine – Italy

- Navantia – Spain (four submarines)

- Naval Group – France

- Chantiers de l’Atlantique – France

- Chantiers Piriou – France

- CMN – France

- Umoe Mandal Shipyard – Norway

- Schelde Naval Shipbuilding – Holland

- Damen Shipyard – Holland

- Elefsis Shipyards – Greece

- Remontowa Shipbuilding – Poland

- Boustead Naval Shipyard – Malaysia

- Hyundai Heavy Industries – Korea

- ST Marine – Singapore

- PT Pal – Indonesia

- Arsenal de Marinha do Rio de Janeiro – Brazil

In recent years, Garbarino received many orders for the Italian and Qatari Navies (several types of ship built at Fincantieri in Italy), the Netherlands Navy (a combat support ship built at Damen Schelde in Holland), the French Navy (logistic support ships built at Chantiers de l’Atlantique in France), the Belgium and Netherlands Navy (mine countermeasure vessels built at Chanters Piriou in France), the Bulgarian Navy (patrol vessels built at MTG-Dolphin in Bulgaria), the Philippine Navy (landing platform docks built at PT Pal in Indonesia), and the Polish Navy (signal intelligence ships built at Remontowa in Poland).