The US Naval Surface Warfare Center (NSWC) Dahlgren Division has collaborated with students from the University of Virginia to support research into additive manufacturing (3D printing) capabilities.

The partnership has been established via the Naval Engineering Education Consortium (NEEC) and is said to be positively impacting the US Navy programmes.

NSWC Dahlgren Division engineer Dr Tabitha Apple Newman said: “Additive manufacturing research, in particular, reaches across technical fields and capabilities and allows Dahlgren to immediately better evaluate and design products for its customers, whether for gun prototypes, special-use technologies, chemical, biological and radiological (CBR) defence, or electric weapons.”

3D printing is a new technological capability that is intended to serve as an alternative to the existing manufacturing technologies used by the US Navy, which are primarily based on casting, forging and machining.

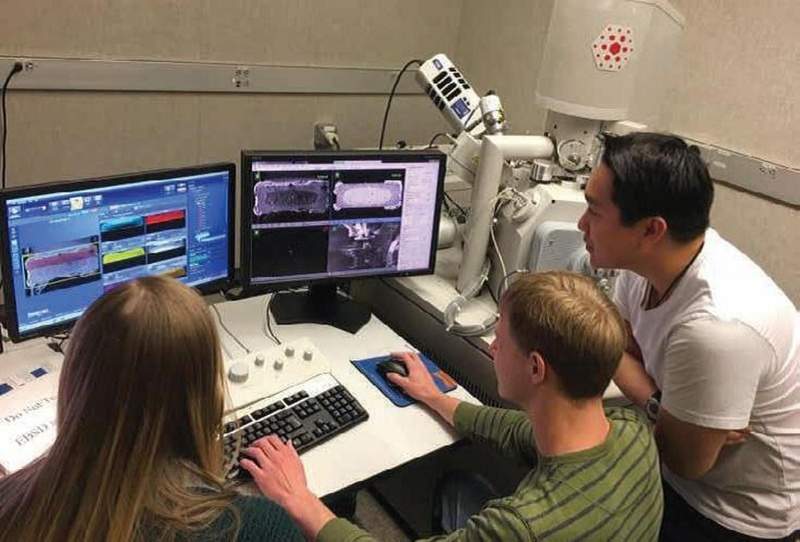

The current research project aims to develop quantitative connections among materials’ process parameters, microstructure and properties, which would represent an important step towards the qualification of additively manufactured parts that can be used in critical load-bearing components.

The project also intends to combine the extensive and advanced heat treatment, characterisation, testing and analysis capabilities used at the University of Virginia, along with the additive manufacturing capabilities at NSWCDD.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataNSWCDD engineer Ricky Moore said: “The research that the University of Virginia is conducting is an important examination of the microstructure and mechanical properties of alloys relevant to the navy, produced by state of the art additive manufacturing techniques.

“Understanding these properties is paramount as the navy begins to design, develop, produce and field components and systems produced with additive manufacturing to improve performance and availability of systems in the fleet.”