3D Systems has entered a collaborative project for the development of metal additive manufacturing technologies in order to help increase the adoption of 3D printing in the construction of US Navy warships.

The deal will see the company partner with Huntington Ingalls Industries‘ (HII) Newport News Shipbuilding division to support various future qualification and certification programmes required for the implementation of advanced manufacturing technology for the navy.

The collaboration forms part of a major technological transformation named Digital Shipbuilding (iDS), which is currently being carried out by Newport News Shipbuilding.

3D Systems and HII will move portions of their traditional production processes to additive manufacturing under the initiative, which is expected to increase the production rate of high-accuracy parts, while ensuring a reduction in wastage and supporting significant cost savings.

3D Systems has delivered and installed the ProX DMP 320 high-performance metal additive manufacturing system at the Newport News shipyard as part of the arrangement.

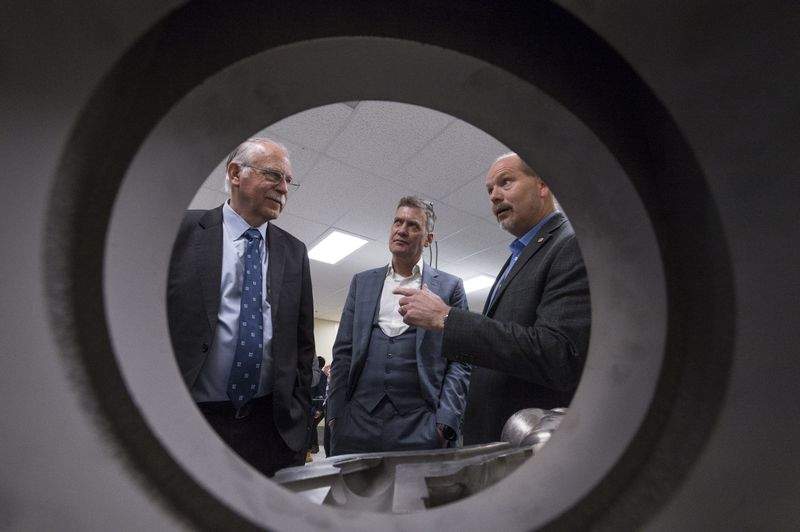

Commenting on the partnership, 3D Systems Metals and Healthcare executive vice-president and general manager Kevin McAlea said: “3D Systems is pleased to play an integral role in transforming the naval shipbuilding industry.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalData“The ProX DMP 320 printer system, combined with our team’s expertise in metal 3D printing technology, will bring new, digitally enhanced geometries to Newport News Shipbuilding, enabling higher performing warship components and ultimately more efficient, cost-effective parts delivery to the US Navy.”

The advanced metal 3D printing machine can be used to produce three-dimensional, marine-based alloy replacement parts for castings or other fabricated parts such as valves, housings and brackets for the US Navy’s future nuclear-powered vessels.