Burleigh are the official distributor and technical support for DUNLOP Low and Medium Pressure Fenders. Other associated products provided are Quick Release Mooring Hooks and Laser Docking Monitoring Systems. Since the mid 1960s the company has introduced unique fendering and docking systems for naval vessels including submarines and also for commercial Ports & Terminals.

- Dunlop Low Pressure Fenders

- Quick Release Mooring Hooks

- Laser Docking and Monitoring Systems

- Fendering Supply and Consultancy

DUNLOP LOW PRESSURE FENDERS

Dunlop Low Pressure Pneumatic Fenders evolved from the need to provide fendering which would avoid high specific pressures upon the hull structure of vessels. Suitable for berthing and mooring naval vessels either ship to shore or ship to ship, the Dunlop low pressure fenders have been used worldwide in many applications and scenarios. Benefits include:

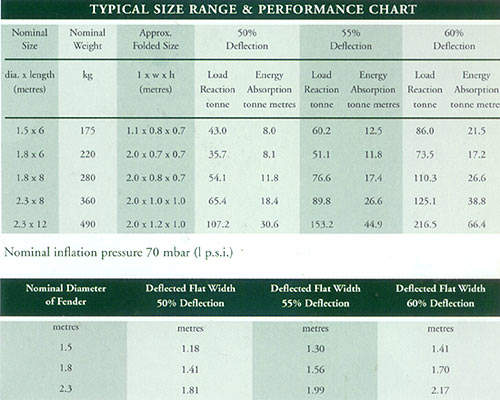

- Greater Choice of Size: available in a standard range up to 4.5m Ø x 30.0m long and suitable for all types of naval ships – also manufactured to individual lengths suitable for specific applications

- Fast Deployment, Easy to Stow and Transport: uniquely deflatable and easy to pallatise, stowage requires minimal space and even the largest unit can be handled with ordinary ships or dockside gear

- Versatile: for small vessels and high speed surface craft, but not limited to these, two small fender sizes to UK MOD (N) specification D/NSC/ES221/238/7/06/01 are in regular use – lightweight and easily stowable, these fenders may be deployed vertically or horizontally on the side of the craft

- Performance and Compression: Dunlop fenders rely only on the compression of air which provides a consistent, reliable performance – the fenders provide high energy impact performance at very low ship hull pressures

- Internal Air Pressure: air inflation pressure of Dunlop LP fenders is only 0.070 bar equivalent to an initial hull pressure of 703kg/m² lower than any other standard type

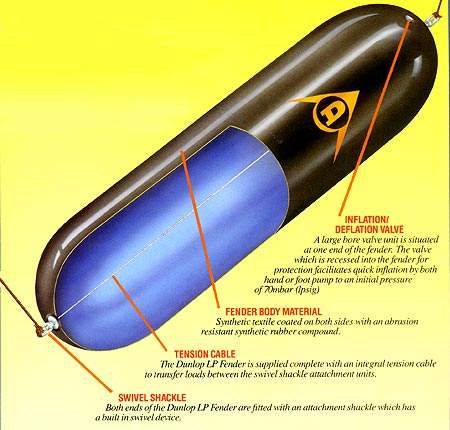

- Safety: no external reinforcement and protection are necessary which is particularly valuable on tanker or specialised hull coverings, as the absence of metal fittings precludes the risk of fire through sparking, etc.

- Construction: – made from polychloroprene proofed nylon fabric and/or high tenacity nylon cord, and specially sewn sections provide remarkable durability

- Easy Repairs – most minor repairs can be carried out on the spot with the kit provided – major repair and servicing facilities are available as well as training of personnel

QUICK RELEASE MOORING HOOKS

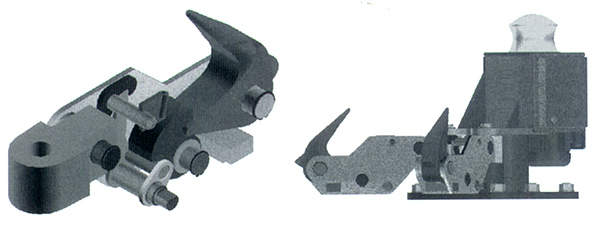

Burleigh offer Quick Release Mooring Hooks, related control system and hardware. The primary use of this mooring equipment is to allow instant release of all or selected ships mooring lines at the throw of a remote or local control lever/switch.

Circumstances for use of Quick Release Hooks (QRH) are generally when there could be a need for rapid undocking of a vessel due to fire, pollution or explosion hazard which prevents access to ship moorings from a conventional bollard, or simply necessary to get a vessel off the berth as fast as possible to isolate and prevent a problem from spreading from one to the other, or prevent a vessel sinking on and blocking the berth.

QRH are also used on remote mooring points where access is difficult or distant, also to improve efficiency and/or economy on rapid turn round berths such as ferry terminals. They are used instead or with conventional bollards.

LASER DOCKING SYSTEMS

This state of the art technology, developed and tested in 1998, enables safe and accurate mooring procedures. Class 1 (fully eyesafe) lasers integrated into docking systems have proven results in the reduction of accidental damage. Statistical studies show that terminals without laser docking systems have an accident one in every 1000 berthing operations compared to one in every 10,000 berthing operations at terminals with laser guided systems.

The laser docking system is able to monitor and compensate for velocity and distance, the angle of approach, exact stress of berthing impact, tide influence, wind and current, as well as dolphins movement monitoring and drift warning.

FENDER SUPPLY AND CONSULTANCY

Fenders are no longer considered as an afterthought or an unwanted expense or luxury. They are today an integral part of the docking and mooring system, cargo handling operations, compatible with both ship and dock structure. Recognised as a technology and industry in its own right, fendering forms part of British Standard BS 6349 Design of Marine Structures.

Burleigh have a long and successful track record in fender design. Over the years the company have satisfied thousands of installations world-wide for commercial ports, offshore and naval operations. These include many naval ports, naval shipbuilders, mooring fenders for USA Trident and UK Polaris submarine programs, wheel fenders for guiding commercial and naval ships into dry-dock or through sea locks including The Panama Canal.

Burleigh can also provide a one-stop integrated package design for Laser Docking Approach and berth monitoring, fenders and mooring or QR hooks.