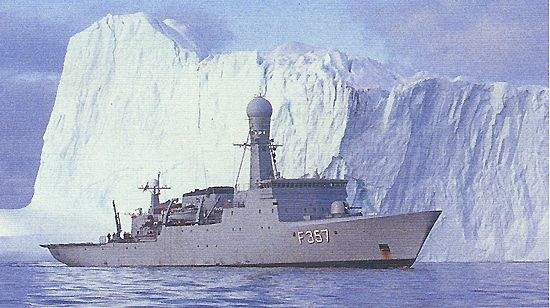

Four Thetis class frigates for the Royal Danish Navy have been built by the Svendborg Shipyard with headquarters on the island of Funen in Svendborg, Denmark. The Thetis (F357) and Triton (F358) were commissioned in 1991, and Vaedderen (F359) and Hvidbjornen (F360) in 1992.

The Thetis Class are multi-role frigates for fishery protection, surveillance, air-sea rescue, anti-pollution and ice reconnaissance.

THETIS DESIGN

The frigates have a double-skinned hull divided by ten bulkheads into watertight compartments. The basic hull shape corresponds to that of a high-speed trawler. There are no bilge keels, but stabilisation is achieved by a combination of fin stabilisers from Blohm and Voss and a controlled passive tank system supplied by Intering.

The frigates are ice-strengthened and are able to proceed through 80cm of solid ice. The hull has an icebreaking bow and stem lines suitable for operations in ice with only one propeller. To minimise ice formation on the superstructure, all winches, capstans, etc. are placed under deck. The allowed amount of icing is 375t.

Maximum continuous speed is 20kt in 4m seas. The ships can stand wind gusts of 150kt during light ice conditions and operate in all sea conditions at speeds of 4kt to 5kt. The ships have an endurance of 8,300nm at varying speeds with a 10% fuel reserve.

COMMAND AND CONTROL

Infocom Electronics, based in Sonderborg, Denmark produced the frigate’s integrated information system, which is based on a digital fibre-optic switch with digital multipurpose subscriber stations.

The system handles all internal and external communications, including data link and message handling for the ship’s Command, Control and Communications (C3) system, supplied by Terma Elektronik of Lystrup, Denmark.

WEAPONS

The armament consists of one Oto Melara 76mm Super Rapid main gun, one or two 20mm guns from Oerlikon and depth charge throwers. The Super Rapid gun has a rate of fire of 120 rounds a minute and range of 16km. The fire control system is the Saab Systems 9LV 200 mk3. A FLIR Systems Inc AN/AAQ-22 SAFIRE thermal imaging system is used for surveillance.

HELICOPTER

The frigate has a landing deck with a landing spot for a single helicopter. Helicopter support arrangements include a Glide Path Indicator (GPI) and a flight refuelling system. The hangar is equipped for helicopter maintenance and has capacity to hold a Lynx helicopter without having to fold the helicopter tail.

SENSORS

The frigates are fitted with a BAE Systems AWS-6 air and surface search radar operating at G band, a Terma Scanter Mil surface search radar operating at I band, a Furuno FR-1505 DA navigation radar operating at I band and a Saab Systems 9LV mk3 fire control radar operating at I and J bands.

Sonar equipment consists of a Saab Systems hull-mounted type CTS 36 RDN and a Thales Underwater Systems (formerly Thomson Marconi) TMS 2640 Salmon Variable Depth Sonar (VDS).

COUNTERMEASURES

The countermeasures suite includes the Thales Defence Ltd Cutlass radar warning receiver, a Thales Defence Scorpion radar jammer and two Sea Gnat launchers for chaff and infrared flares.

PROPULSION

The propulsion machinery consists of three MAN B&W V28/32 diesel engines with combined power of 9,000kW. The fitted bow thruster is able to hold the bow against an athwartship wind of 28kt. A retractable azimuth thruster is capable of propelling the ship at 10kt.

The bow and azimuth thruster are produced by Brunvoll A/S. There is also a shaft generator of 1,500kW, supplied by Volund Motorteknik A/S, and three GM diesel motors with Volund Teknik generators, each with an output of 480kW.

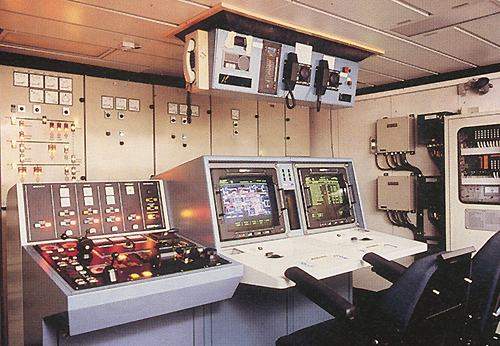

The machinery is controlled by an integrated ship control and surveillance system (SCSS) designed by Soren T. Lyngso. The system allows the vessel to sail with unmanned engine rooms, the entire installation being controlled, and visually supervised from the bridge or from other locations in the ship.