Seven Sandown Class ships have been built to the batch 2 design. Design changes include accommodation for female officers and ratings, bigger Voith Schneider propulsion units, a more powerful crane for underwater vehicle deployment and a bigger, improved decompression chamber for divers.

Both batch 1 and batch 2 Sandown Class vessels were built by Vosper Thorneycroft at their Woolston yard. Five batch 1 vessels were commissioned between 1989 and 1993. Cromer (M103) was decommissioned in 2001.

Three Sandown minehunters were also built by Vosper for the Royal Saudi Naval Forces under the Al Yamamah programme, commissioning in 1991-97.

Batch 2 Series: HMS Penzance (M106) was commissioned on 14 May 1998; HMS Pembroke (M107) in November 1998; Grimsby (M108) in 2000; Bangor (M109) and Ramsey (M110) in 2001 and Blythe (M111) in 2002. The last, Shoreham (M112) was delivered in November 2001.

In July 2004, the UK Ministry of Defence announced that three Sandown class minehunters would be retired by April 2005 in a restructuring of the UK Armed Forces.

Bridport was decommissioned in July 2004, Sandown in January 2005 and Inverness in April 2005. In September 2006, Estonia signed a contract to acquire the three vessels. Sandown (now EML Admiral Cowan) was delivered in 2007, Inverness (renamed EML Sakala) in January 2008 and Bridport (EML Ugandi) in January 2009.

In May 2005, it was announced that the eight Sandown Class vessels would change homeport from Portsmouth to HM Naval Base Clyde in Scotland. This change was effected in June 2006 and the squadron is now known as MCM1 (mine countermeasures 1).

HMS Grimsby returned to operational service in March 2008, following repairs after a grounding incident in Norway in 2006. In June 2009, Babcock was awarded a contract to upgrade HMS Blyth.

Sandown Class design

Sandown Class minehunters are built almost entirely of non-magnetic materials and are designed to resist high shock levels. Their manoeuvrability is controlled, either manually or automatically, by using the Ship Position Control System (SPCS) developed by Vosper Thornycroft.

Production techniques have been re-examined in the construction of batch 2. A major change is the increased use of SCRIMP (Seeman Composites Resin Infusion Moulding Process). The SCRIMP fibre-reinforced plastic technique involves the resin being drawn into a sealed mould under vacuum. Vosper Thornycroft’s manufacturing process uses SCRIMP technology for the entire superstructure and for some internal structures of minehunters.

Command and control

Sandown Class vessels are fitted with the BAE Systems Insyte (formerly Alenia Marconi Systems) Nautis M combat management system.

Insyte was awarded a contract in January 2005 for the upgrade of Sandown Class systems to Nautis 3. Nautis 3 has mine countermeasures mission software which can control navigation, mine detection, classification, remote disposal and ship manoeuvring.

A number of Sandown vessels have been fitted with the Royal Navy’s new successor identification friend-or-foe (SIFF) system, supplied by Raytheon Systems (RSL) of Harlow, Essex.

Sandown Class gun

The ship’s main armament is an Oerlikon 30mm gun with a range up to 10km and a firing rate of up to 650 rounds a minute.

Mine countermeasures

The Sandown Class is equipped with two underwater PAP 104 mk5 remote-controlled mine-disposal vehicles, supplied by Societe ECA. The vehicle is controlled via a 2,000m fibre-optic cable. A lighting system, low light level black and white camera and a colour camera are fitted. The vehicle is also fitted with a high-resolution sonar. The sensor data is transmitted back to the operations control centre on the ship.

The main payload is a 100kg mine disposal charge which can be replaced by a manipulator. Wire cutters are used to release moored mines from the column of water above the sea bed. The mine disposal vehicles can be deployed to a depth of 300m.

In January 2006, Ultra Electronics was awarded a contract to supply Atlas Elektronik SeaFox expendable mine disposal vehicles to replace the PAP 104 on the eight Sandown vessels.

The batch 2 Sandown Class ships have had a more powerful crane installed for deployment and recovery of the remotely controlled vehicles.

Countermeasures

The ship is equipped with two Barricade lightweight decoy launchers supplied by ML Aviation of Andover. The launchers are capable of dispensing infrared decoys and chaff in confusion, distraction and centroid seduction modes of operation.

Sensors

The sonar system is the Thales Underwater Systems Type 2093 variable depth sonar which is deployed from a well in the hull.

The sonar is a multifunction system operating in VLF and VHF bands. The Type 2093 employs five arrays for mine search and classification modes of operation.

The ship is equipped with Type 1007 I-band navigation radar supplied by Kelvin Hughes.

Propulsion

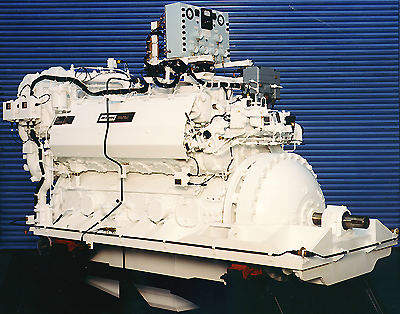

The ship has an advanced propulsion system with very low magnetic and acoustic signatures. The ship is equipped with two Alsthom Paxman Valenta 6RP200E diesel engines each developing 1,500shp. The engines are fitted with degaussing coils.

The propulsors are supplied by Voith Schneider America Inc of New York. The propellers are non-magnetic and silent running. The material is mainly stainless steel with bronze blades. The input to each propeller is 475kW at 1,200rpm. The ship also has two Scottel bow thrusters. The diesel engines provide a maximum speed of 13kt and the ship’s speed is 6.5kt on the electric drive.