A new division of NUCAP Industries, NUCAP Energy (NUCAP) has launched the unique GRIPMetal™ surface enhancement technology for improved thermal energy transfer and significant reinforcement of composite materials. By supporting innovation in key industries, such as transportation, computing, power generation, renewable energy, aerospace, and heating, ventilation and air-conditioning (HVAC), NUCAP aims to create a more sustainable and energy-efficient future.

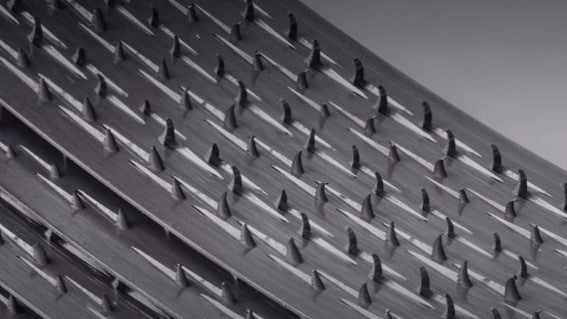

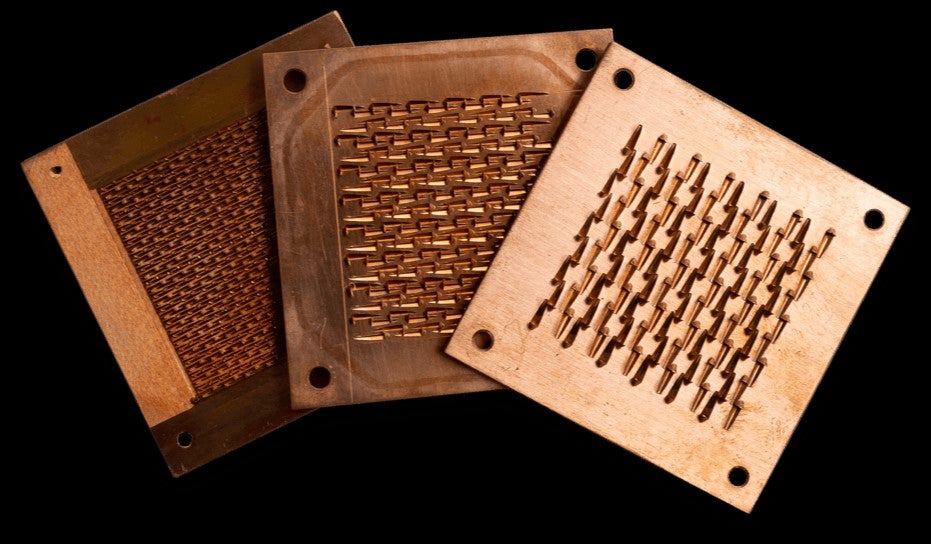

GRIPMetal™ is fabricated using a patented non-subtractive process that enhances the metal surface by forming rows of ‘Velcro-like’ hooks, substantially increasing surface area without any increase in the material weight. Working with metal substrates, such as stainless steel, aluminium, copper, brass and titanium, NUCAP’s GRIPMetal™ manufacturing process substantially enhances the rate of thermal energy transfer.

When used in composite materials, GRIPMetal™ simultaneously improves both the structural strength of the material (substantially increasing its ballistic properties) and its thermal properties, lowering both the cost and mass of the element. The material also provides efficient shielding against electromagnetic radiation.

Battery-powered vessels

As transportation solutions evolve to combat climate change, battery power is increasingly seen as the way forward. Vessels powered by alternative fuels and energy storage solutions will need high-efficiency cooling systems to keep electronics and motors running smoothly.

By efficiently removing excess heat, NUCAP’s surface modification technology increases battery life and capacity, thereby maximising a vessel’s service lifespan.

Heat management for on-board computing and electronics

Cooling capabilities are a continuing challenge to the exponential advancement of computing. With computing systems increasing in power and shrinking in size, equally advanced heat management is needed to maintain efficiency.

Many naval processes rely on computers and electronics, making heat dissipation critical to the reliable running of a vessel; NUCAP surface modification technology provides the perfect means to accomplish the goal of increasing performance capabilities and extending component lifespans.

An additional function that GRIPMetal™ can play in the design of cooling components for dissipating heat from electronic devices, is its ability to shield parts from electromagnetic interference.

Naval HVAC

From large rotary and crossflow exchangers to hydronic plate exchangers, different types of heat exchangers are all suitable for surface modification, which can substantially increase the efficiency of both heating and cooling functions in HVAC systems.

Surface modification decreases the footprint of HVAC devices, resulting in smaller equipment and components; this, in turn, lowers the embedded energy of HVAC devices. Furthermore, higher efficiency reduces greenhouse gas emissions and contributes to conservation of resources.

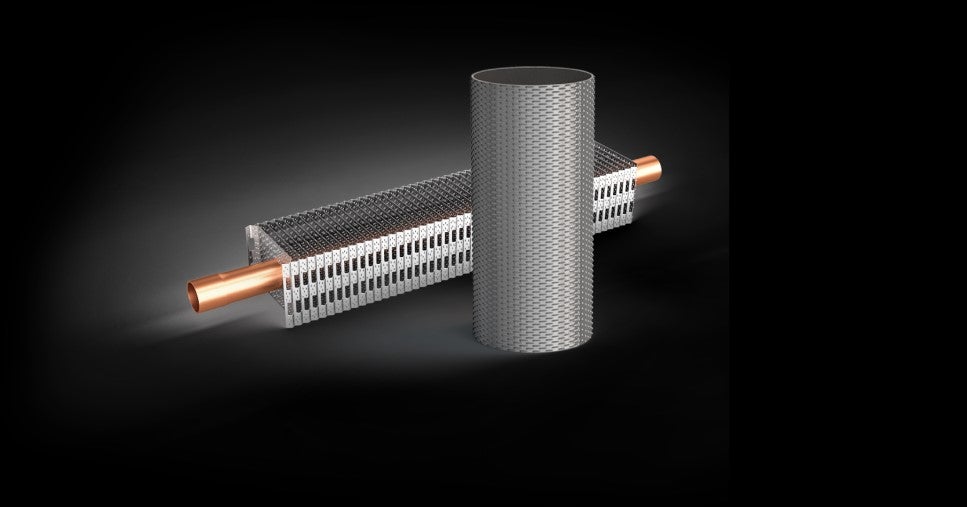

Enhanced surface materials can also be used as both the inside and outside of pipes and tubes in HVAC applications, such as evaporators and condensers. The thousands of hooks of the GRIPMetal™ material increase the available area for heat exchange and ‘penetrate’ layers of fluid positioned next to the surface for even more efficiency.

About NUCAP Energy

Based in Canada, NUCAP Energy is dedicated to improving the efficiency of thermal processes and increasing the strength of composite materials using the innovative manufacturing technology of GRIPMetal™.

With more than 21 years of experience in state-of-the-art manufacturing technology from parent company NUCAP Industries, NUCAP Energy provides metallic materials to key industries. NUCAP’s manufacturing plants are located across Canada and the US to supply patented GRIPMetal™ materials to its customers.